Identify inefficiencies, cut manual errors, and unlock ROI

Identify inefficiencies, cut manual errors, and unlock ROI

Stop Guessing. Start Streamlining.

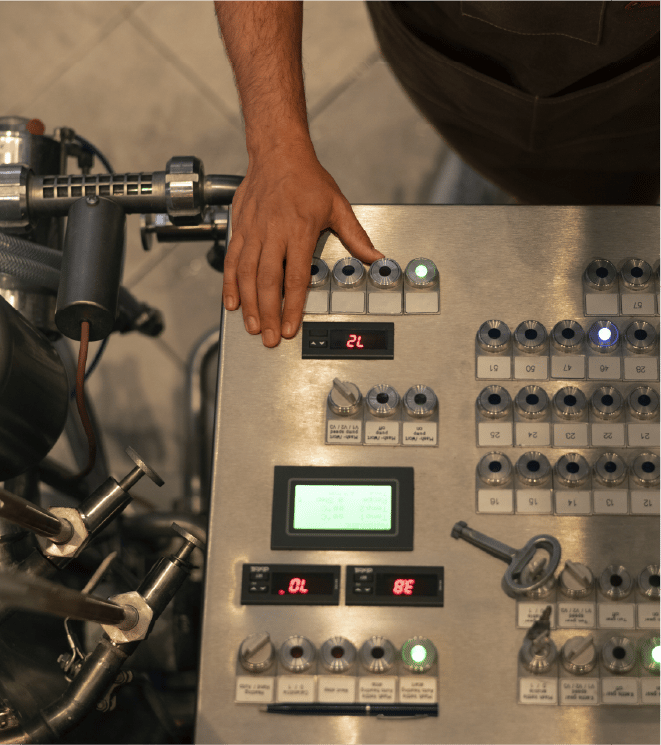

Manual processes, bottlenecks, and underutilized machinery silently inflate your costs. Gradion’s Factory Automation Audit gives you data-driven clarity on where automation makes the biggest difference.

What’s in the Audit Package?

| Deliverable | Description |

| Automation Audit Report | Line-by-line breakdown of processes with inefficiency and automation-readiness indicators. |

| Automation Opportunities & ROI Analysis | Clear recommendations with investment vs. return scoring. |

| Implementation Roadmap | Step-by-step phases for rollout, including downtime risk, training, and budget needs. |

| Executive Debrief Presentation | Slide deck summarizing current state, proposed automation, and expected business impact. |

Your Factory Partner for Real Automation Gains

-

Deep experience in automotive, electronics, F&B, logistics

-

Independent tech advisory + hands-on implementation

-

AGV/robotics, MES, PLC/SCADA integration experts

-

Asia-based delivery + EU-grade engineering & compliance

by 22% without disrupting production

Factories Facing

Manual or semi-automated lines

High variability in process timing

Lack of real-time production visibility

Missed production targets or traceability failures

FAQs

What’s included in a Factory Automation Audit?

A review of shop-floor processes, system integration, downtime risks, automation potential, and investment-return projections.

How long does it take?

Most audits are completed within 2–3 weeks.

Will operations be interrupted?

No. We run our diagnostics with minimal to no disruption to live production.

Do you help execute the automation roadmap?

Yes. Gradion supports implementation from control systems to software and training.

Can this work with our existing MES/ERP?

Yes. We integrate with most major MES/ERP systems or advise on extensions.

FREE CHECKLIST DOWNLOAD

Automation Bottlenecks:

What Factory Leaders Must Know

Automation offers significant potential, but many factories face the same five operational and technical obstacles before achieving measurable ROI.

This concise checklist enables factory leaders to identify these challenges early, assess their operational impact, and prioritize corrective actions before committing additional resources.

What You’ll Actually Get

In this short checklist, we’ve boiled down what we’ve seen across dozens of factory audits around the world.

It’s not theory. It’s what’s really holding plants back from making automation work: